Industron Solutions

SMART INDUSTRY

AR glasses can provide multimedia remote guidance interaction capabilities which are based on first-view audio and video, AI intelligent recognition capabilities, and augmented reality capabilities, to empower industry customers, and help customers to achieve mobile operation management, and improve market competitiveness.

WAREHOUSE LOGISTICS

The operator continuously scans the identification code on the package through the AR glasses, displays key information such as the cargo destination and priority, and performs picking and review according to the optimal path guidance planned by the glasses.

SMART EMERGENCY

When working at remote places, front-line personnel wearing AR glasses to operate according to smart work orders issued in the background. When problems or malfunctions are encountered, experts can access them at any time for remote guidance

REMOTE ASSISTANCE

Wearing AR smart glasses, experts can remotely connect to the first site, guide the on-site staff to solve the fault, and improve communication efficiency through text, voice, video, pictures, screenshots, markup, video sending, and AR overlay..

SECURITY

In smart security, ar glasses can be used in mobile law enforcement to perform face recognition, certificate verification, and license plate recognition. AR glasses can receive and display high-altitude images taken by drones and remote command and information in real-time, realizing air-ground coordination and three-dimensional prevention and control

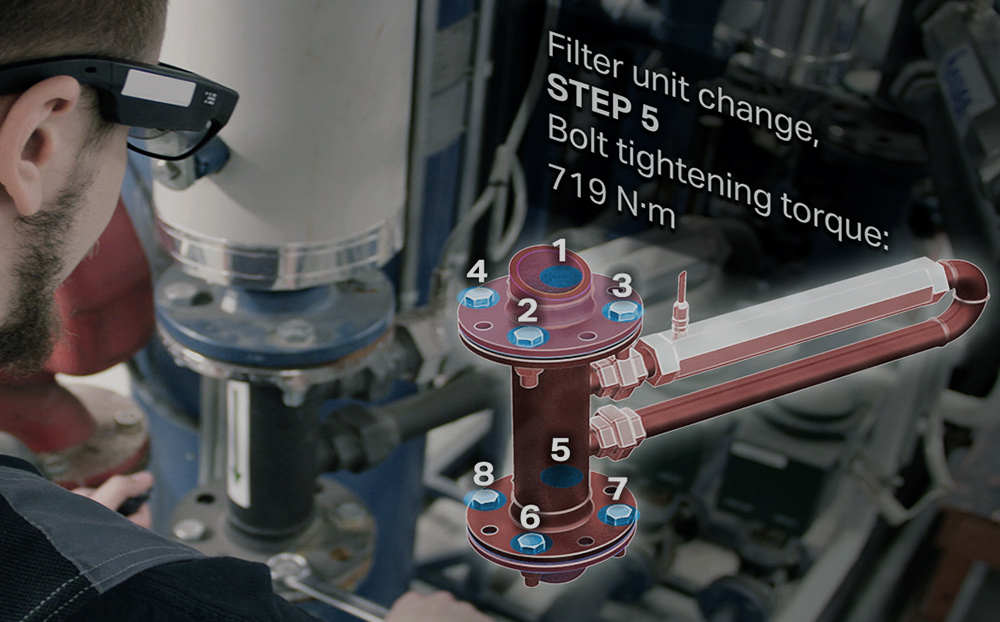

MAINTENANCE & INSPECTIONS

AR Inspection The AR inspection solution provides intelligent assistance to traditional inspection operations. By utilizing AR, big data, cloud computing, and other technologies, it enables real-time data viewing, remote expert assistance, operational guidance, and live recording. This not only enhances inspection efficiency but also reduces operational and labor cost

AR TRAINING & KNOWLEDGE CAPTURE

By utilizing technologies such as image recognition, object recognition, spatial positioning, and virtual-real overlay, AR training transforms everyday training and video teaching programs into virtual simulation training. This addresses the challenges of "inaccessibility, invisibility, immobility, and difficulty in replication" in practical training